-

Posts

2097 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Media Demo

Store

Collections

Videos

Posts posted by rocking.that.eclipse

-

-

I watched this last week on my lunch break. I watch all your videos when they pop up.

You actually persuaded me to look into the amps I'm thinking of getting for my daily (audio art, if I can find a set I like).

Great work and keep it up man

-

Been following this on FB over the last couple days.

I actually just picked up a stray this weekend too and am keeping it. Terrible what people who can't afford or don't want an animal anymore will do.

-

1

1

-

-

Haha the places I've worked that we have one of those we call it a "Dong"

-

On 5/31/2017 at 3:02 AM, TonyD'Amore said:

Two of the tweeters are in parallel with two others. 2 of the amplifier channels running at 2 ohms when in SPL mode

Thank you sir. I thought there may be something like that going on

-

This is an awesome idea.

-

How does one fit 14 speakers on 12 channels? Just wondering because I can't figure it out

-

8 hours ago, audiofanaticz said:

The basket diameter wont matter so much since he is making them for his subs, and not making them to reproduce and sell, so as long as his measurements are good, their should be no issue.

No matter what with t-nuts, the constant torque from woofers being installed and removed will oblong the holes where the spikes dig in since metal is stronger than mdf, "birch" plywood people use.

I used some t-nuts in my skates to mount the plates and was even skeptical doing that, but since I wont be removing the plates from the boots repeatedly there shouldnt be an issue.Insert nuts imo are by far superior than t-nuts, for mounting woofers, or beauty panels, or anything that may see a lot of in and out. Plus you can drop a couple drops of epoxy on them before screwing them in, and you will strip out the bit long before the insert nuts thinks of budging.

Only thing I would suggest with with threaded inserts is to not use a cheap screw for them. I used a 18-8 Stainless Socket Head Button Screw and a lot of them stripped out

-

13 minutes ago, never knows best said:

a hand full of t-nuts would accomplish the same goal for maybe 1% of the cost.... not to mention the huge waist of material and machine time-

or am I missing something?

I used threaded inserts last year (basically a stronger alternative to t-nuts) and i broke 1 basket and had to literally dismantle my baffles to get the subs out.

I decided this year to personally not flush mount and just screw into the wood....

-

49 minutes ago, audiofanaticz said:

Because usually when people have things machined it is usually aluminum or some other soft metal and not steel.

If you didnt want people to assume, you should of said otherwise....

Touche lol

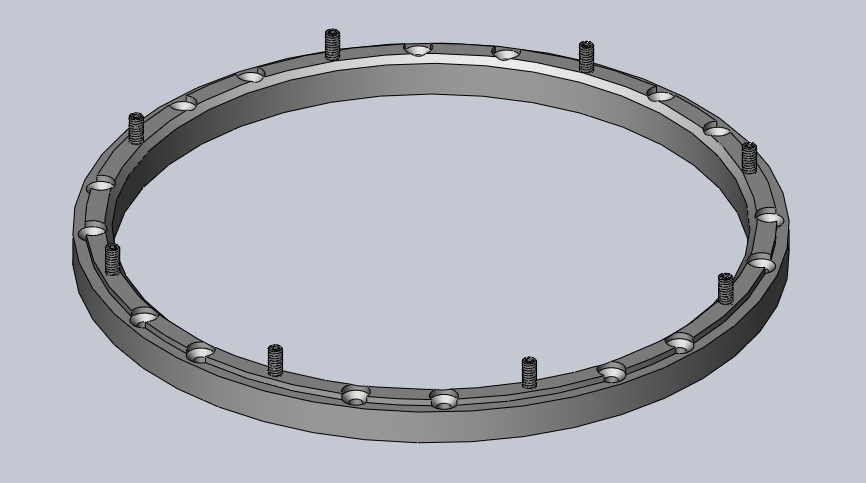

Yeah steel for strength of studs. I couldn't find a good way to machine out of aluminum and attach the studs

-

1

1

-

-

21 hours ago, audiofanaticz said:

as long as the aluminum studs hold its a pretty nifty idea!

who said anything about being aluminum....

ASTM 1018 is prolly what we will use or A36 since its cheap steel and can be welded as needed

-

1

1

-

-

4 minutes ago, srp365 said:

do you CNC the stud holes, then tap and put in all thread? Just curious.

Couple ways of doing this.

We could tap the holes and contersink with some head clearance and fill the head with weld

The way I think we are going to go with this one is drill all but the last 1/8th inch of material and tap down to it. That way if something happens to stud it can get removed.

-

36 minutes ago, srp365 said:

That's bad ass. If basket sizes were standard, that would be worth selling. I can see how that would make mounting heavy ass subs a lot easier, especially if you made 2 of the bolts longer on top.

Price is too much for selling I think. We are going 3/4" thick on.

We'll see I know what 8 of them will cost so we'll see what someone thinks they are worth when they are done

-

2

2

-

-

This is going on the outside of the box to fill up the spot where it used to be flush mounted. With the subs removed you should be able to drill and bolt everything in through the sub cutout

-

1

1

-

-

-

-

Shane Sullivan 6 hours 21 min and 50 seconds

-

1

1

-

-

1 hour ago, fyerbyrd22 said:

then the agm was bad...mixing agm with lithium helps, not hurts...unless the agm is already shit

False. AGM is brand new and load tested perfect. In testing we found that under load the lithium was feeding the agm faster than the alternator could even thought the alternator is 8 inches from battery. This lithium was feeding the front battery before it was feeding the amp.

I can try to do a video for you this weekend. If you look at a topic on the xs power tab on here called lithium weirdness you'll see.

-

well he is running a 36k spl and 2 6ks but he only has one 270 amp alt

He used a agm up front and with that his voltage is 10 volts. He removed his agm and his voltage is not 12.8 at idle full tilt

-

On 12/20/2016 at 0:26 AM, bigp88 said:

I own a 15k and according to xs power they shine at around 11.8 so if your looking to get the most out of ur amp don't do it

i know this is old as hell but I'd like to say now from testing that your problem is that you use agm and lihtium.

Pull the agms and try with just the lithium and I bet you your voltage will be better. My buddy is running the same amp setup as you with only 1 alt and just 1 lihtium and is seeing 12.8 full tilt at idle

-

-

21 minutes ago, corey0928 said:

Anyone ever use protein shakes for a meal substitute? Was told to try that when working out and trying to lose weight

I used to do this when I was in school back home. I also accompanied it with like a granola bar or a pb&j

-

On 2/10/2017 at 8:29 PM, _paralyzed_ said:

My spanish isn't great but I'm pretty sure that said "I would like to eat your a**hole"

-

On 1/20/2017 at 10:49 AM, reedal said:

Did you clamp the current from the lithium to the amp(s)? The alt may only be outputting 85 because it only needs to make 85....

Pulling 325 dynamic

with load tester it was pulling 400 and only putting out 85....

-

16 hours ago, SnowDrifter said:

Lithium and lead/acid are going to have different resting/usable voltages. Based on what you described I suspect the lithium rests a bit higher than the d3400

Where are you load testing/reading voltage from?Did a multitude of places trying to see if he had some parasidic drop in current or voltage from a bad ground.

Skar Audio LP1000.1d - 1000 Watts for 129 Bucks? AD-1 Amp Test and Giveaway inside! Claim 3 spots! UPDATE - WINNER PAGE 195!

in SKAR AUDIO - (READ ONLY ARCHIVE)

Posted

SKAR AUDIO FTW 1000.1 CLAIMED